Solutions

- Solutions

-

Industry Solutions

- Project Cases

-

Industry SolutionsDelivering One-stop Solutions for Intelligent Production

-

Project CasesLeveraging Intelligence for Sustainable Productivity in Future Factories

Flagship Products

Flagship Products

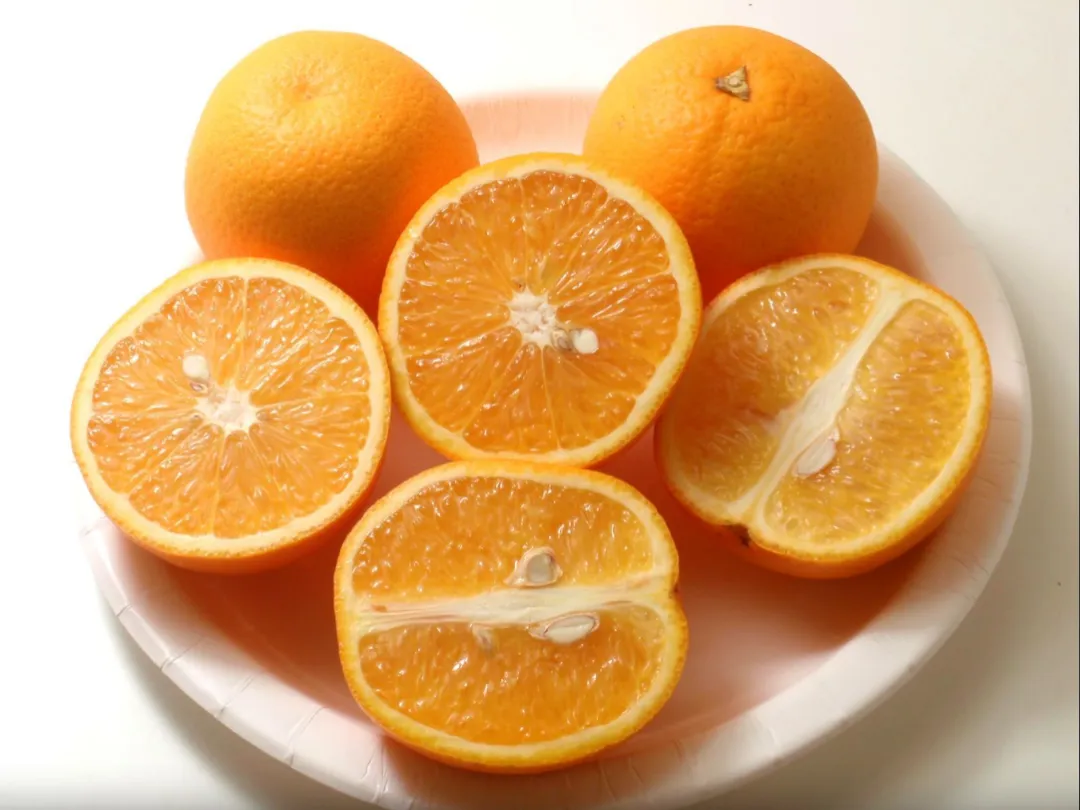

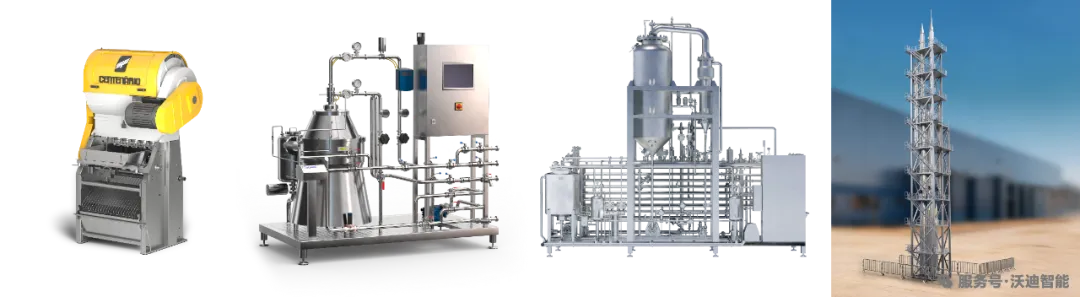

Food Engineering

Biological Engineering

Biological Fermentation System

TARS cell perfusion regeneration system

5L bioreactor system

Parallel bioreactors

Duplex bioreactor system

Multi-parallel fermentation system

Two-stage bioreactor system

Multi-stage scale fermentation

Continuous disinfection system of culture medium

Manufacturing of Large Fermentation Equipment In-house

Liquor Engineering

Laboratory & Pilot Plant

Exchanger

MINI Tabletop Sterilizer

PT-20T Mini UHT Tubular Sterilizer

PT-20P Mini UHT Plate Sterilizer

PT-SS Mini UHT Scraper Sterilizer

PT-30DT Mini UHT Steam Injection Sterilizer

PT-50DT Mini UHT Steam Injection Sterilizer

PT-100T Pilot Tube Sterilizer

PT-20C Mini UHT Tube-Plate Hybrid Sterilizer

Margarine and Spreadable Fat Processing Equipment